The founder of the modern modular home manufacturing company SCANDI, Serhii Lotsman, began his career in architecture. However, he quickly realized that traditional construction is a constant improvisation, where each new client means a new project and new mistakes. To change this reality, he created a system in which the result is always predictable — just like in the best technological products.

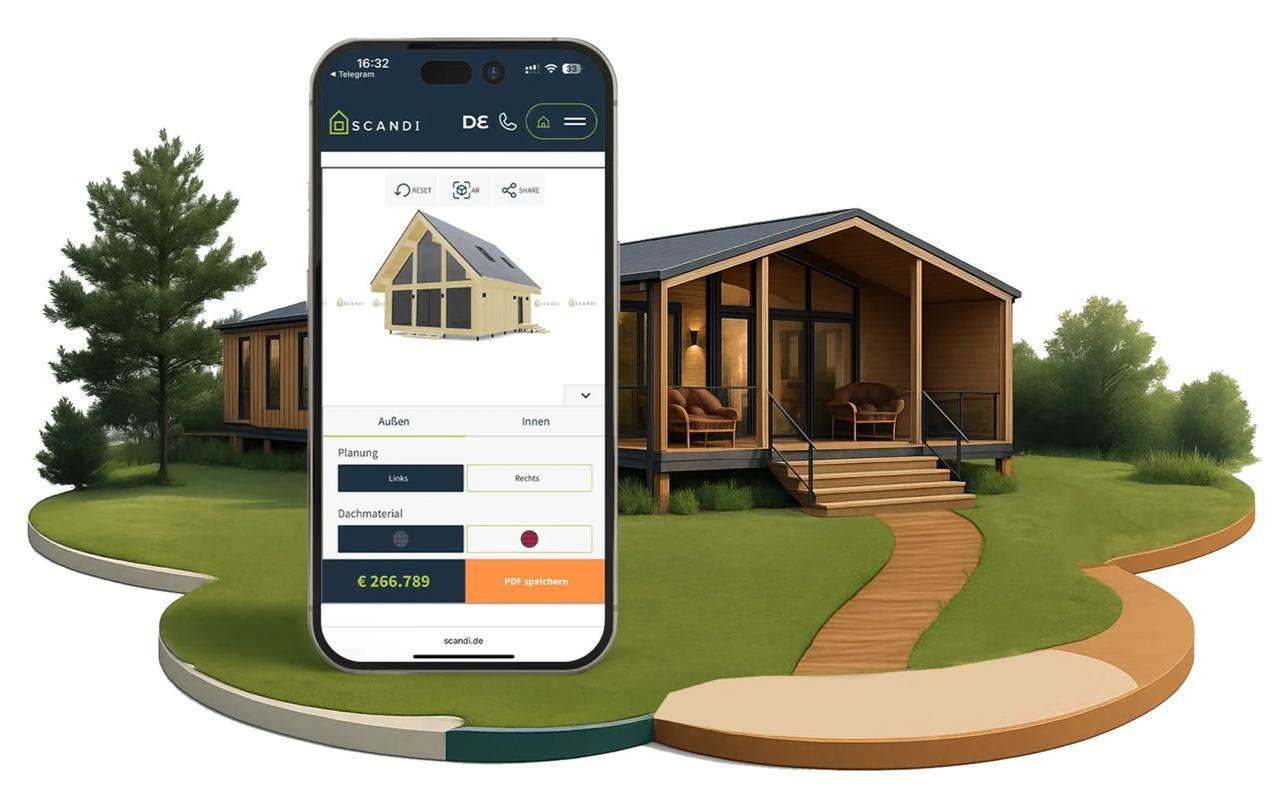

According to the philosophy of SCANDI, a home is not about years of planning, approvals, and dozens of contractors — it’s a ready-made solution with fixed quality, functional design, and transparent pricing. Its new product, DABL (Digital Architecture Builds Living), is a SaaS platform that makes construction digital. Clients can configure a modular home online within minutes, visualize it in VR/AR on their own plot, and receive the keys to their finished home in just 45 days.

In partnership with SCANDI, we share details about the product itself and how it works, as well as the company’s European expansion and future plans.

Content

How SCANDI Began

We built our first team as a product company. We were joined by architects who understood UX; technologists who thought systematically; and designers who knew how to create a positive user experience. It was a team that thought not in terms of construction stages, but user scenarios. That’s when the DNA of SCANDI was formed — precision, aesthetics, and repeatability.

We wanted to think like Apple, but in the housing category. Every product should be intuitive, scalable, and beautiful. Not just functional, but beautiful — because beauty is part of quality.

As of 2025, over 1,300 SCANDI homes have been built. They are located in Ukraine, Germany, the Netherlands, and other European countries. But these numbers reflect not only scale — they also represent the evolution of the process itself.

With each new home, we learned, optimized processes, and improved the system. Today, a SCANDI house is born not from a drawing on paper but from data synchronized in real time between the architect, production, and the client. In other words, we have turned construction into a digital cycle with clear algorithms.

For us, a modular home is not just an alternative to concrete — it’s an alternative to postponed living. Right now, there’s a fundamental cultural shift happening: people no longer want to wait five years for construction — they want to live now. We’re witnessing a transition from the concept of “building” to “ordering,” where a house becomes a one-click product — like a smartphone or a car.

Production Launched in Germany and Office Opened in Amsterdam

In 2025, SCANDI launched its own production facility in the German city of Uelzen, Lower Saxony. From that moment, the company has been operating on two bases — in Ukraine and Germany — with a combined capacity of over 3,500 m². That’s enough to produce around 200 homes per year.

But for SCANDI, this result isn’t about big numbers — it’s about the confidence that we’ve built something truly sustainable. Owning a factory in Germany is not the ultimate goal but rather proof that the technology works.

Why start with Germany? Because it’s a country where trust is built not on words but on process quality. Everything here is about precision, responsibility, and craftsmanship — and we wanted to test our system in exactly such conditions. This decision brought us three key advantages.

- The Made in Germany label opens doors that would remain closed for an imported product.

- Logistics to clients in Germany, the Netherlands, and Denmark are significantly reduced.

- In 2023, SCANDI obtained a Handwerkskammer Germany license, granting the right to carry out production activities throughout the European Union. This provides access to a unique craft culture that values quality over speed and results over process.

We also opened an R&D office in Amsterdam — it operates as a design lab. Here, the team tests interfaces, works with VR/AR, and integrates an AI consultant that helps clients choose their home and supports them from the first click to signing the contract. We chose Amsterdam because it’s home to architecture studios, design startups, and companies that set trends in PropTech and UrbanTech.

The next step is scaling. Our digital system DABL allows other manufacturers to build SCANDI homes — and there’s no need to open new factories for that. It’s enough to integrate our standard into their production, and tomorrow such houses can appear in France, Denmark, or anywhere in the world.

You can learn more about SCANDI on the official website here

Scaling Challenges in Europe That SCANDI Turned into Advantages

The biggest challenge we faced in Europe was the speed of decision-making. In Germany, every step is regulated — each operation has its own instruction, procedure, and protocol. Meanwhile, in Ukraine, we’re used to working fast and intuitively, adapting on the go.

At first, this difference seemed like an obstacle, but over time, we learned to turn it into an advantage. We built what we call a “hybrid system” — Ukrainian energy, speed of thought, and creativity combined with German methodical precision, attention to detail, and process discipline.

To become true players in the German market, we went through a complex process of integration. In 2023, we joined the Handwerkskammer — the Chamber of Crafts, which is a mark of recognition in German business culture. And in 2025, I personally obtained a Zimmerer certification — a master’s qualification in wooden construction — which grants the right to produce modular homes across Europe.

What Makes SCANDI DABL Innovative

Simply put, we call our product DABL an operating system for development. It’s the first tool of its kind and scale in the construction industry. Imagine being able to see a house as a digital object — from the first idea to the final installation — and manage the entire process online in real time.

DABL is housing-as-a-service, much like how Tesla sells not just a car but an entire ecosystem. We are transforming the housing market from a physical product phase into a digital service phase, where every element is synchronized within a single system.

In DABL, we managed to unite into one synchronized system three worlds that have always existed separately — architecture, production, and the end user.

Previously, the architect designed the project, the manufacturer tried to realize it, and the client waited and hoped. Months of time, substantial money, and — most importantly — design quality were lost in between. Each transition from one stage to another was a potential failure point.

DABL eliminated these barriers by creating a continuous data flow. When the architect makes a change to the project, the production team instantly sees how it affects materials and timelines. When the client chooses another option, the system automatically recalculates the cost and updates the visualization.

This model has the potential to grow into a “European unicorn” because it deals not only with square meters but with digital infrastructure. Architects can create their own collections of homes in the DABL library, developers get a powerful dashboard for managing entire neighborhoods, and marketplaces can integrate ready-made solutions into their ecosystems.

How to Create Your Product in DABL

The customer journey in DABL is more like configuring a premium-class car than ordering traditional construction. The user opens the SCANDI Configurator and enters an intuitive environment. Here, they choose the base home model, define the area, experiment with layouts, and select finishing materials. Each choice is instantly reflected in a 3D visualization.

Once the client is satisfied with the result, they click “Order.” All data automatically goes to the production module, where the real work begins — ordering materials, planning production, and coordinating logistics. From the first click to the installation of the finished home on the site takes about 45 days.

More information about the DABL product is available here

How the SCANDI Standard Will Benefit the European Market

The European housing market is going through a systemic supply crisis. Demand for new housing significantly exceeds construction rates, and the shortage is already measured in millions of units.

Construction has slowed sharply due to a combination of factors: inflation has driven up material costs, bureaucratic procedures stretch approvals for months, and the industry still operates without unified digital standards. The average cycle — from idea to project completion — takes 12 to 24 months, and most processes are still done manually, with paper documents and endless approvals.

The paradox is that we live in the digital age, yet houses are still built using methods that haven’t fundamentally changed in the past half-century. However, DABL shortens timelines and increases process predictability. What usually takes 12 to 24 months now requires just up to 2 months. But we’re not just speeding up the process — we’re creating a new market logic, where housing is data, not endless paperwork.

What’s Next

The 2025–2026 period is dedicated to scaling DABL as an independent product that goes beyond the company’s internal needs.

We are launching the DABL Partner Network for architects, developers, and local manufacturers in Denmark, Poland, Austria, and the Netherlands. The main goal is to create a system that flexibly adapts to local conditions in each country while consistently maintaining global quality standards.

Ukraine remains the intellectual heart of SCANDI — the R&D center where design, IT development of the DABL platform, and architectural modeling are concentrated. It’s fundamentally important for us to show that Ukrainian professionals can create a global, European-level product — from concept to implementation. This is about positioning Ukraine as a technological nation.

In five years, SCANDI will become not just a company but a platform for creating next-generation housing. We want buying a home to be as easy as buying a smartphone: choose, customize, order online.

But it’s not just about physical structures — we’re building a data architecture around how people want to live. We don’t export finished products; we create them within each market. We don’t sell square meters — we sell the experience of living.

Spelling error report

The following text will be sent to our editors: