In 2020, Ukrainian startup Releaf Paper made a real breakthrough in the field of eco-innovation. The young company created a formula for paper from fallen leaves. It all started with the scientific work of schoolboy Valentyn Frechka. It has grown into a business that launches production facilities in France and other EU countries.

The eco-startup received a grant from Google and won the EIC Accelerator 2022 program from the European Commission. The team cooperates with L’Oréal, Chanel, BNP Paribas, LVMH, and Logitech. Oleksandr Sobolenko, CEO of Releaf Paper, told MC.today journalist Alyona Mezhakova what other countries Releaf Paper will launch in, why it is difficult to find technicians in France, what agricultural waste can be used to develop eco-friendly packaging, and how the search for new production formulas is progressing.

Content

- 1 From gadgets to ecology: about the start of cooperation with the startup Releaf Paper

- 2 At the beginning of the full-scale invasion, most investors did not even want to talk

- 3 Company mission and cooperation with global brands

- 4 Experimenting with markets and customer segments

- 5 Labor costs are determined by the diploma: peculiarities of hiring personnel in France

- 6 Opening of production in France and plans for Ukraine

- 7 Grants for awards to the world’s first producer of fallen leaves

- 8 Making our way to perfect packaging through challenges and opportunities

- 9 We want to develop innovative eco-packaging in Ukraine

- 10 We plan to make a license model of Releaf Paper and master new raw materials

From gadgets to ecology: about the start of cooperation with the startup Releaf Paper

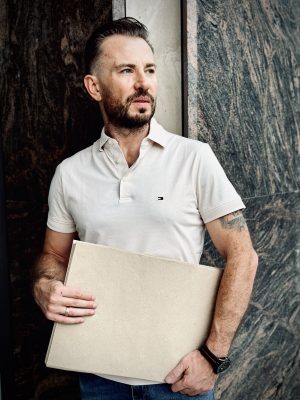

I worked in investment and entrepreneurship for ten years. I created and managed companies related to consumer electronics. In particular, in the area of smartphone recovery and re-introduction to the market.

My company Rephone is one of the first on the Ukrainian market. Our gadget exchange programs operated in many national networks. In 2021, my share of the business was bought by Asbis (the exclusive distributor of Apple equipment in Ukraine).

Even then, I was thinking about creating a new promising project, related to the circular economy. But the plan changed a bit. I learned about the Releaf Paper school project and wanted to be a part of it.

Back then, it was a classic hard-core startup early stage. I had a vague strategy, organizational chaos, and an imperfect product. I inherited a «inherited» database with several hundred requests from business clients who wanted to buy products. We didn’t have it yet because we didn’t have our own production. And contractors were reluctant to work with us.

Therefore, first of all, we had to contact our clients and look for opportunities to fulfill their requests. We came up with a strategy, which, with adjustments, we still follow. The transformation process lasted a year. We changed everything that could be changed. And now I can say that there is not a trace of the school project left — we have grown into an international company.

At the beginning of the full-scale invasion, most investors did not even want to talk

In February 2022, there were two of us in the team. I was based in Kyiv. My partner Valentyn worked remotely at home in the Zakarpattia region. The day of the invasion shocked us. For the next few days, of course, we had no time to think about the companyIn mid-March, we gathered our thoughts and developed a plan. We continued our work, but with a focus on the EU market. We decided to build the first large production facility in an EU country and started looking for investors remotely. As expected, most of them did not even want to talk to us. The uncertainty factor was decisive.

However, during this time, we became active members of the Ukrainian Startup Fund community. Thanks to this, we attended a number of international startup events in 2022. We have made a loud statement in Europe. We were financially supported by Google for Startups and WWF. This gave us an impetus for international activities.

Company mission and cooperation with global brands

Releaf Paper’s mission is to convert green waste into pulp for packaging production in a way that is environmentally friendly. We help cities get rid of fallen leaves in an environmentally friendly way. In addition, we provide the paper industry with alternative sustainable raw materials. The positive environmental impact of our operations is a consequence, not an end in itself.

To get to the final product as you see it (for example, a paper bag or box), we need to involve three different types of production lines. For each stage, we turn to contractors. Currently, we cooperate mainly with a paper mill in the city of Zmiiv, Kharkiv region. And most packaging contractors are located in Kyiv and Kyiv region.

Our first client was the Ukrainian branch of L’Oréal. Chanel, Schneider Electric, and Samsung followed. Recently, we started cooperation with BNP Paribas, LVMH (Louis Vuitton, Moet, Hennessy), and Logitech.

Such clients are hard to find. They never respond to cold calls. These companies contacted us themselves. With some of them, our cooperation was limited to pilot orders, as for them, it was just marketing. With others, we have been working for three years. Most of our European clients are industrial players who produce packaging for brands, so their names are not familiar to the general public.

Labor costs are determined by the diploma: peculiarities of hiring personnel in France

When we opened an office in this country, the hardest thing was to get used to the local mentality and rhythm of work. Here, it is very different from what we are used to. The main difference is that Ukrainians are hardworking, efficient, and result-oriented. In France, everything is very slow and expensive. Local legislation differs quite a bit. Those wishing to open a company here should take into account the language barrier, as half of the country does not speak English. The level of bureaucracy, trade unions, labor costs, and working week restrictions should also be taken into account.

The number of employees in France will increase from 4 to 10 by the end of the year. By 2026, we plan to increase this number to 35 people. I personally select specialists for key positions. For technical positions, we engage a local recruiting agency

French labor law is very complex. First of all, employees are more expensive compared to Ukraine. The cost of labor often depends not on the efficiency of a specialist or his achievements, but on his theoretical qualifications, determined by the level of education and diploma.

For the simplest technical work, it is difficult to find an employee with a salary of less than 2.5 thousand euros per month. A mid-level specialist is at least 4 thousand euros. Senior positions cost 7-10 thousand eurosIn addition, the company pays up to 45% of taxes on employee salaries. The social package is an obligation and is defined by law. The employer pays for insurance, transportation reimbursement, food vouchers, etc. The payroll system is so complicated that French companies use consultants to calculate salaries and social contributions.

In France, the system of contracts with employees is mandatory. We offer contracts with a limited duration, but the French are not very attracted to them. They prefer unlimited ones. The nuance is that it is extremely difficult to dismiss an employee with such a document. This is always accompanied by huge financial compensationIn addition, France is a country of revolutions and strikes. We treat our employees with extreme tolerance, as demarches are the norm in this country.

Opening of production in France and plans for Ukraine

The main plan for this year is to launch its first own production facility in France, a pulp mill. Other programs will depend on this.

Now the local team is planning the activities of the future factory, selecting premises, and resolving organizational issues. We have placed an order for equipment. Installation work is planned for June. In July, we hope to launch the first stage of production.

Initially, we wanted to build facilities in the city of Lyon. Our company is registered there. We negotiated with the municipality for nine months to supply us with leaves. But the city could not guarantee the required amount of raw materials. We quickly went around to several dozen other key cities in France. Finally, we agreed on the required volume with a company located near Paris. That’s why we decided to relocate our production place next door.

We are considering various countries for this purpose, which, for the most part, contact us themselves. However, our resources are limited, as each factory requires EUR 5 million in investment and 2 years of implementation time. Therefore, we create some competition between interested countries, trying to get certain preferences from them. First, we need leaves, which local authorities should provide free of charge in a certain amount. Secondly, we need additional financial support: local grants or incentives to reduce our own investments.

We can build a factory in any country that has the right amount of raw materials and proximity to our consumer. For example, after negotiations, Finland and Estonia are not a priority. Instead, The Netherlands is the most active. After France, our production may appear there.

Let’s not forget about Ukraine — we have plans here We want to invest EUR 500 thousand in raw materials production in Kyiv region. The project is in the process of preparation and coordination with financial partners. It will be a smaller copy of our French processing facility.

Grants for awards to the world’s first producer of fallen leaves

We managed to get grants from Google and EU, as the world’s first producer of paper products from fallen leaves. Become the winner of the EIC Accelerator 2022 from the European Commission. We are the finalists of the LVMH Awards 2023, participants of the LVMH accelerator program.

Our high success rate is due to good planning and effective implementation. There is also a hidden benefit — the jury members fall in love with the Releaf Paper concept.

Compete It is difficult to compete for a grant from the European Commission with 6 thousand companies. But we have a rapid potential for growth and scaling. And we have a team that is unique for a startup — most people have extensive experience in international corporations. In addition, we have engaged high-quality consultants.

Making our way to perfect packaging through challenges and opportunities

Our main competitive advantage is that the world is looking for new materials. We are the only ones who produce paper from fallen leaves. Thanks to this, companies such as P&G, Nestlé, and McDonald’s come to us.

Of course, there are plenty of challenges and some demand we cannot meet. Paper color is one of them. The barrier to food contact is another. We cannot carry out certification because we do not own the enterprises, and this greatly limits us in Western markets.

In addition Made in Ukraine is not only an image advantage, but also a number of problems for our clients. For example, military risks, expensive logistics, problems with blocking the border, etc.

We want to develop innovative eco-packaging in Ukraine

We are currently producing products and have resumed sales through our Ukrainian online store. We offer different types of packaging to business customers. It is already made and we send it to the next customer after the order.

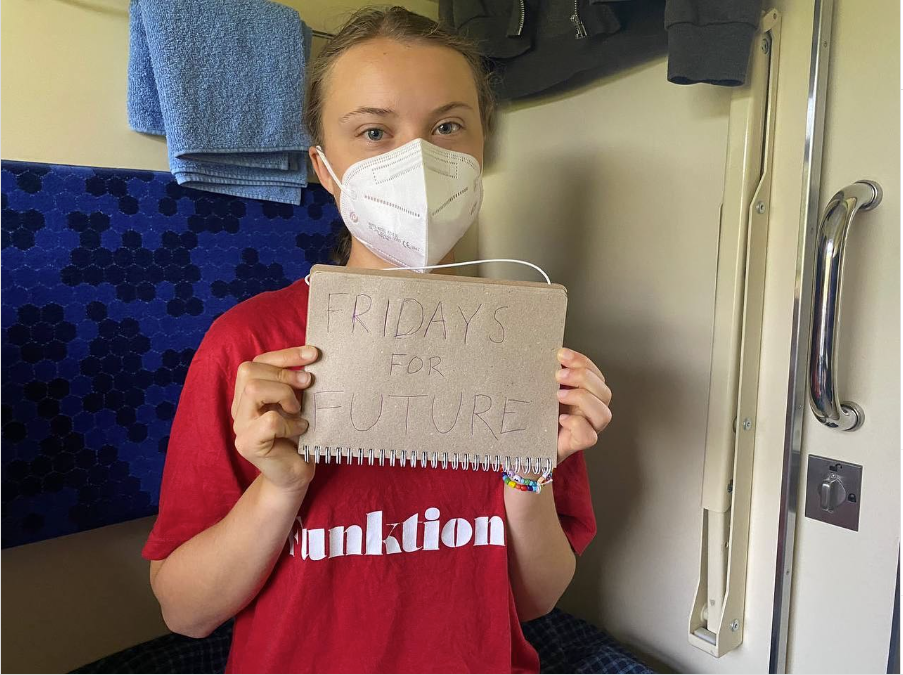

In addition, we customize the packaging for the client’s needs by applying their branding. However, this service is subject to a minimum order, as we are technically unable to produce very small batches. The assortment of the Ukrainian warehouse includes paper bags, boxes, envelopes, wrapping paper (which can be used for printing or drawing), and souvenir notebooks. Everything is made in Ukraine.

The country lacks a culture of smart consumption and sorting practices. There is a lack of understanding of the carbon footprint left by human or business activities. That’s why we had to explain to every second client in Ukraine why paper or packaging made from fallen leaves is an investment in the future. Instead of burning the leaves, they are processed into valuable raw materials, preventing carbon dioxide emissions. Our technology reduces the use of electricity and water, which in turn has a positive impact

After use, our product can be recycled with other paper. Or you can compost it at home It decomposes in 55 days. And most importantly — every ton of Releaf fibers replaces fibers from 17 trees. This is a contribution to forest conservation.

We plan to make a license model of Releaf Paper and master new raw materials

My dream is to build an international company that will change the market. We see the future in the ability to process millions of tons of waste into valuable raw materials around the world. We are working on finding new applications not only in the paper industry, but also in the textile industry, construction, etc.

We will not be able to build new factories forever, so we aim to switch to a license model of cooperation. This will enable industrial players from the US, Canada, Brazil, and Japan to produce pulp and paper from waste using our technology. It doesn’t matter who creates the paper from fallen leaves, as long as it bears our company’s name.

We are also looking at another raw material – agricultural waste. Before the war started, we had a pilot project with the Japanese corporation Sumitomo. Back then, we studied pineapple leaves. In the Netherlands, we studied the stems and leaves of cucumbers, tomatoes, and tulips. All of these can be processed using our technology with almost the same efficiency. So expect new materials in the coming years!

Author: journalist MC.today Alyona Mezhakova

Spelling error report

The following text will be sent to our editors: