Engineers from the Massachusetts Institute of Technology (MIT) have created a flexible and durable metamaterial made of acrylic plastic.

The metamaterial is composite material, composed of many structures at the microscopic level. Usually, different structures combine to provide properties such as flexibility, softness, and strength.

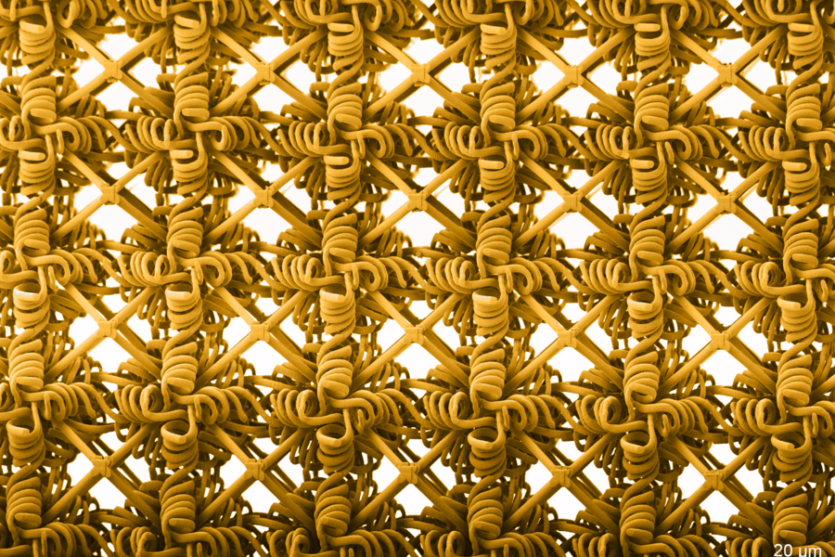

According to the MIT developers, their material combines rigid mesh frame with posts and trusses — a geometrically unchanged supporting structure consisting of rectilinear rods, the nodal joints of which are considered to be hinged in the calculations. with spiral structures that weave around each post and truss.

— a geometrically unchanged supporting structure consisting of rectilinear rods, the nodal joints of which are considered to be hinged in the calculations. with spiral structures that weave around each post and truss.

The structures are made of acrylic plastic and printed simultaneously using laser printing technology called two-photon lithography. According to MIT professor Carlos Portela, it is worth imagining structures tangled around the lattice, similar to spaghetti. Destroying the lattice structure itself does not destroy the individual structures tangled around it.

«When we destroy a monolithic grid, these broken parts stay with us, and now all these «spaghetti» get tangled in the parts of the grid This promotes more entanglement between the woven fibers, which means more friction and more energy dissipation», — explains Carlos Portela.

Researchers tested new material by attaching both ends to a special nanomechanical press. In this way, they measured the force required to break it. It turned out that the new double-mesh design could stretch three times its own length.

The developers claim, that some printed designs can give the new metamaterial exceptional strength and resistance to physical deformation. Engineers MIT is confident that the new metamaterial can be used to make elastic ceramics, glass and metal alloys that are resistant to tissue tearing, and strong and flexible scaffolds on which cells can be grown for tissue repair.

The material also opens up the possibility of creating flexible semiconductors and protective chip enclosures. Gadgets and computer components such as motherboards and video cards using this material can become more durable and reliable.

Spelling error report

The following text will be sent to our editors: