Specialists from the The School of Engineering at the Hong Kong University of Science and Technology has developed a new flexible alloy made of titanium and niobium, which heats up when stretched and cools down when compressed.

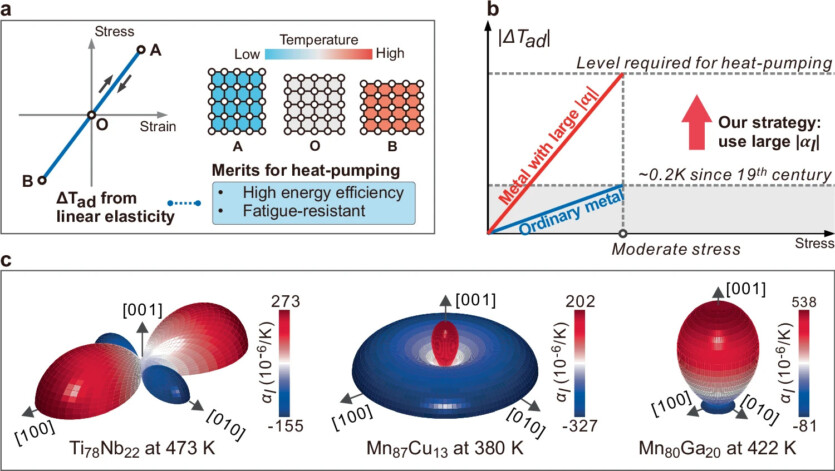

It is noted that the innovative Ti₇₈Nb₂₂ alloy heats and cools 20 times more efficiently than conventional metals. This makes it an alternative to traditional technologies vapor-compression heating and cooling.

Whereas traditional metals during stretching heat up by no more than 0.2°C, the temperature of this alloy changes by 4-5°C due to the phenomenon called thermoelastic effect. The properties of the alloy can be compared to modern cooling systems that use special gases and chemicals as refrigerants.

The alloy reaches 90% of the efficiency of the ideal Carnot cycle, which is the limit of the ideal thermal cycle. At the same time, traditional solid-state pumps are limited to 50-70% of the ideal Carnot cycle.

«This discovery changes the long-held and well-established notion that the thermoelastic effect is too weak to be useful. Our research shows that linear elastic deformation alone can be used for highly energy-efficient thermal pumping», — the researchers emphasize.

According to them, similar alloys with special properties that change shape and temperature under pressure are called ferroelastic, capable of changing their own temperature even more — by about 22°C.

Currently, heating and cooling systems account for half of the world’s energy consumption, mainly due to the burning of fossil fuels. Traditional heat pumps that use phase transitions are less efficient and require the use of chemicals and gases as refrigerants, which exacerbates global warming. The proposed Ti₇₈Nb₂₂ alloy does not emit greenhouse gases, is fully recyclable, and works without the need for complex phase transitions.

«This technology provides a transformative solution for replacing fossil fuel heating. The alloy can be used in buildings, industry, and even compact devices, reducing energy costs by 20-30% and carbon emissions», — explains the lead author of the study Dr. Li Qiao.

Ti78Nb22 could become the basis for a new generation of heat pumps. Scientists are already developing prototypes for industry and patenting the technology. The alloys can make the systems even more powerful, cooling a room from 30 °C to 21 °C in 15 minutes. This is especially important as air conditioning accounts for 20% of the world’s electricity.

The results of the study are published in the journal Nature

Source: Interesting Engineering

Spelling error report

The following text will be sent to our editors: