Swedish researchers developed a composite carbon fiber battery that can be used to create the bodies and frames of devices. The battery will actually have no separate weight.

Researchers from Chalmers University of Technology, Sweden, have succeeded in creating a composite carbon fiber battery that is as tough as aluminum and energy-intensive enough for commercial use. Cars, airplanes, ships, or computers can be built from a material that also functions as a battery. Because there is no need for separate batteries, the weight of the devices will be significantly reduced.

According to rough estimates, a battery material could halve the weight of a laptop or make a cell phone as thin as a credit card. The range of an electric vehicle on a single charge will increase by 70%.

Research on structural batteries has been going on at the university for many years. When in 2018 Professor Leif Asp and his colleagues published their first results on how stiff, strong carbon fibers can store electrical energy chemically, this progress attracted enormous attention. News that carbon fiber could work as electrodes in lithium-ion batteries spread rapidly. Physics World ranked this achievement among the ten biggest breakthroughs of the year.

Since then, the research team has continued to develop its concept of increasing both stiffness and energy density. The previous milestone was reached in 2021, when the battery’s energy density was 24 Wh/kg, which means about 20% of the capacity of a comparable lithium-ion battery. Now the density is 30 Wh/kg. Although this is still less than modern batteries, the new ones have completely different working conditions. When the battery is part of the structure and can also be made of a lightweight material, the overall weight of the vehicle is significantly reduced. Then, for example, an electric vehicle does not require as much energy to operate.

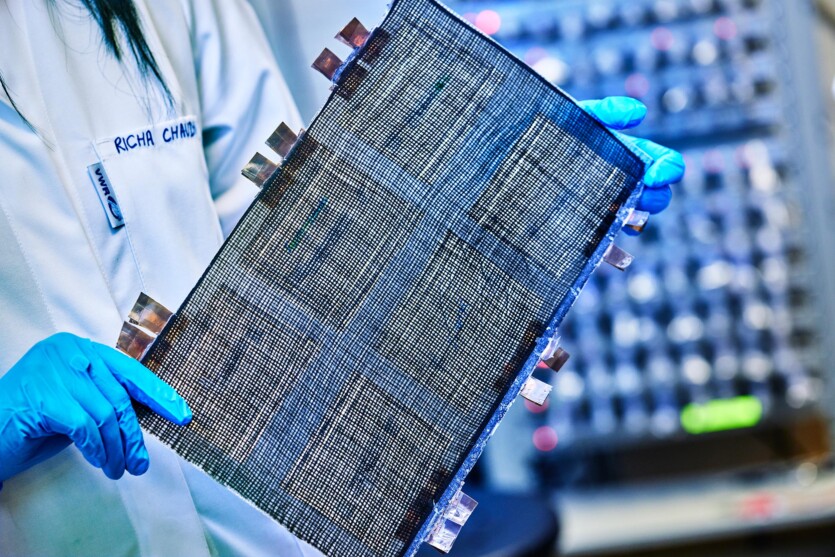

The developed battery concept is based on a composite material and contains carbon fiber as the positive and negative electrodes, where the positive electrode is coated with lithium and iron phosphate. The carbon fiber used in the electrode material is multifunctional. In the anode, it acts as a reinforcement as well as an electrical collector and active material. In the cathode, it acts as an amplifier, current collector and frame for the lithium.

In a battery, lithium ions are transported between the terminals through a semi-solid electrolyte rather than a liquid electrolyte, which is a challenge when it comes to producing high power. This requires additional research. But this design contributes to the battery’s safety by reducing the risk of fire.

«Investing in lightweight and energy-efficient vehicles is a matter of course if we want to save on energy and think about future generations. We have done calculations for electric vehicles that show that they could drive 70% longer than today if they had competitive structural batteries»,” says study leader Leif Asp, professor in the Department of Industry and Materials Science at Chalmers.

When it comes to vehicles, there are high demands on the structure, which must be strong enough to meet safety standards. Scientists have increased the stiffness and elasticity of the material. It can withstand loads as well as aluminum, but at a lower weight. From the very beginning, the goal was to achieve a performance that would allow the technology to be commercialized. In parallel with the ongoing research, market ties are being strengthened. However, there is still a lot of work to be done before the batteries make the step from the laboratory to large-scale production.

Source: SciTechDaily

Spelling error report

The following text will be sent to our editors: