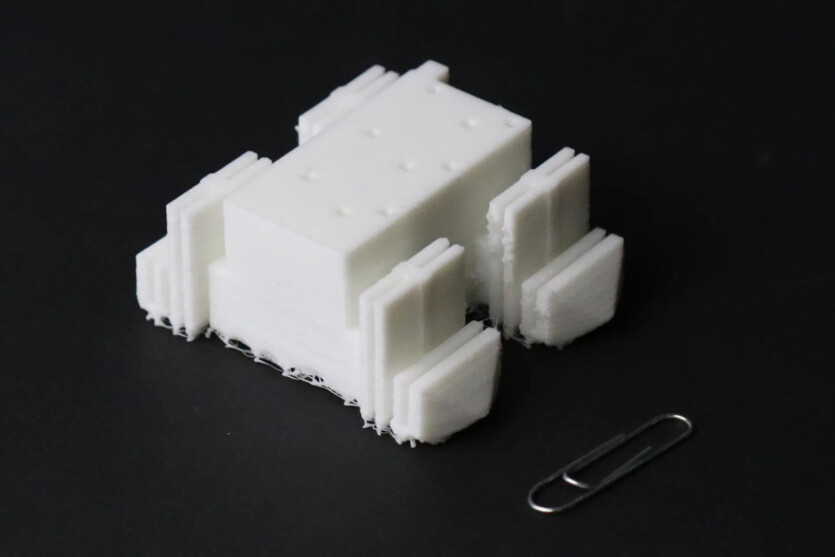

Scientists from the University of Edinburgh have printed a soft robot suitable for mass production on a 3D printer in 9 hours.

It is noted that the created the robot is moving by means of of compressed air. It was created on a $500 open-source Flex Printer 3D printer.

Recently, a similar soft robot was printed by American engineers from the University of California, San Diego. However, it took them 58 hours of continuous work, and the cost of the printer itself was Both prototypes were printed from soft and flexible, thermoplastic polyurethane.

Printing a robot on The Flex Printer is designed to be run «upside down». This device is able to work with materials that were previously thought to be unsuitable for FDM printing. A key challenge in creating soft robots has been the lack of standardized methods. However, modifications to the Flex Printer solve this problem by filamentizing with a diameter of 2.85 mm, which is 7 times more resistant to bending than the standard 1.75 mm diameter.

In addition to this The Flex Printer delivers fast print speeds to minimize defects and has an open design for better cooling. Printing in an inverted position allows you to create sealed channels and thin membranes that do not sag under gravity.

After the printing process is complete, the platform is turned over so that the robot is in the correct position. It is connected to a pneumatic an annular oscillator that will provide an air flow of 2.25 bar to the channels inside the robot. The air pressure sequentially activates two ligament actuators in each leg, which move the limb sideways, and one foot actuator, which lifts the limb off the ground.

«Using our new platform, anyone can now easily print what was previously considered impossible. Without the long-standing manufacturing and design challenges and limitations holding it back, we believe that soft robotics is poised to make a real-world impact», — said one of the study’s leaders, Max Hepner, an engineer at the University of Edinburgh.

According to him, the open architecture of Flex Printer and the publication of all files on GitHub are designed to speed up development. The community can already suggest improvements through the Soft Robotics Forum and Discord server. The platform can potentially find applications in medicine, nuclear waste disposal, and space missions.

The tallest building created by 3D printing was built in Switzerland

The results of the study were published in the journal Device

Source: New Atlas

Spelling error report

The following text will be sent to our editors: