Scientists from the University of Surrey in the UK have used a new method for detecting microscopic defects in welded joints thermonuclear reactors.

Their research makes it possible to create more reliable and safer designs for future fusion reactors. Together with the British The Atomic Energy Authority, The National Physical Laboratory and TESCAN, a scientific instrumentation company, have developed an advanced technology for detecting hidden weaknesses in metal welds at the microscopic level.

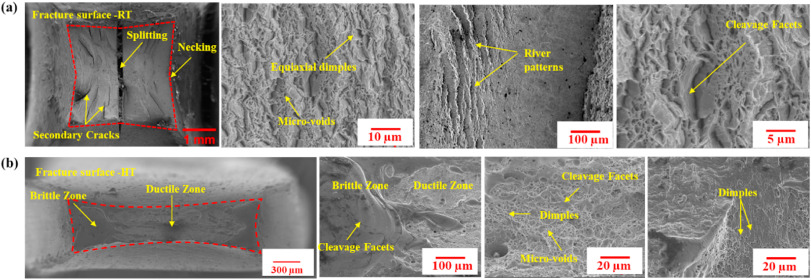

These internal defects that occur during the manufacturing process can pose a threat to structural integrity and durability of reactor components. The study examined the occurrence of such defects in the steel-based heat-resistant alloy P91, which is considered one of the promising materials for future fusion reactors.

Using techniques known as plasma focused ion beam and digital image correlation, the scientists mapped the residual stress in extremely narrow regions of welded joints. Previously, these areas were too small to analyze using traditional methods.

The results of the study showed that internal stress has a serious impact on the behavior of the alloy P91. In particular, the beneficial stress makes some areas even harder, while the harmful stress reduces the strength of a number of other areas, causing the metal to become more flexible and brittle. At an operating temperature of 550°C in thermonuclear reactors the metal becomes more vulnerable and loses more than 30% of its strength.

«Fusion energy has enormous potential as a source of clean, reliable energy to help us reduce carbon emissions, improve energy security and reduce energy costs in the face of rising bills. However, we first need to make sure that fusion reactors are safe and durable», — says study leader and Associate Professor of Materials Science at the University of Surrey, Dr Tang Sui.

According to another author of the study, is a researcher at the Center for Engineering Materials at the University of Surrey, Led by Dr. Bin Zhu, the study offers a realistic assessment of the structural integrity of welds in fusion reactors under a wide range of extreme conditions. This is an important step forward in designing safer and more resilient components for the nuclear sector.

The results of the study were published in the journal Journal of Materials Research and Technology

Source: SkiTechDaily

Spelling error report

The following text will be sent to our editors: