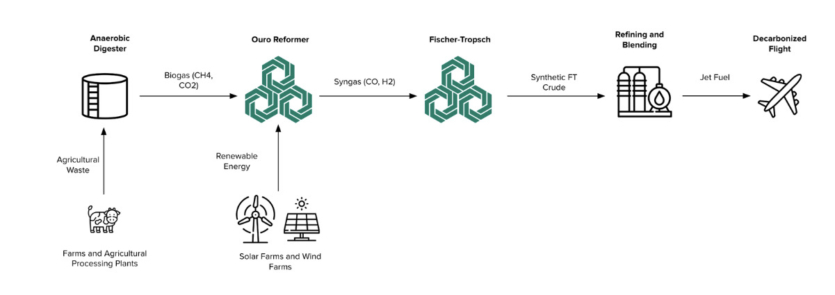

Circularity Fuels, a California-based startup, has introduced a compact reactor for converting biogas into synthesis gas, that can be used for the production of aviation fuel.

The Ouro reactor uses waste from the milk production farm, namely — cow manure. Ouro uses biogas, a mixture of methane and carbon dioxide, produced by the decomposition of manure in lagoons, and turns it into a key component of aircraft fuel.

The synthesis gas can be further processed into jet fuel, using the Fischer-Tropsch synthesis, an industrial method that has proven itself. Representatives of Circularity Fuels say, that the synthesis gas can be produced directly on the farm and then transported for further use.

“Farmers in the US and around the world are sitting on an untapped gold mine. We are enabling them to turn waste into a profitable product that airlines desperately need. For the first time, farmers will become producers of renewable fuels without waiting for pipeline infrastructure that will never come”, — said Circularity Fuels CEO and founder Dr Stephen Beaton.

More than 20 thousand large livestock farms in the United States annually produce almost half a billion tons of cow manure, but biogas is produced from less than 6% of the total volume of this waste. The innovative reactor is 100 times cheaper than traditional technologies for environmentally friendly synthesis gas production.

У Circularity Fuels has successfully demonstrated the effectiveness of its own design and stated, that it will be the world’s first reactor to convert crude biogas from the farm waste lagoon into synthesis gas without the need for combustion. Ouro can be connected to conventional power grids and can directly process raw biogas, bypassing expensive pretreatment steps.

In addition, the reactor can operate stably even in the presence of contaminants that could damage other reformers. The development comes at a time when airlines are facing increasing demands to include jet fuel in their fuel balance. Currently, aviation fuel production covers only 1% of the industry’s needs.

“If SAF’s biogas processing technology is deployed at all recyclable U.S. facilities, waste disposal sites, including farms, landfills, and wastewater treatment plants, it could produce 42 million gallons per day, which would cover 70% of the country’s jet fuel needs”, — Circularity Fuels representatives said in a press release.

This year, the company plans to demonstrate the entire process of processing biogas into jet fuel at a farm in California. By implementing this technology on a large scale, the company could help airlines achieve their industry goals providing quality fuel and enable farmers to earn billions in a new profitable business.

Source: Interesting Engineering

Spelling error report

The following text will be sent to our editors: