Finnish researchers from the University of Turku have created a biofilm from red onion peel to protect solar panels from ultraviolet radiation.

It is noted, that created jointly with scientists from Aalto University and Wageningen University protective biofilm, based on red onion peel, not only completely blocks UV light, but also outperforms commercial plastic-based films. The key ingredient is an aqueous extract from red onion peels.

“Nanocellulose films, treated with red onion dye, are a promising option, when the protective material needs to be biobased”, — says the researcher from the University of Turku Rustem Nizamov.

On the one hand, cells in solar panels convert sunlight into electricity. However, ultraviolet light destroys sensitive components, including the electrolyte in dye-sensitized solar cells (DSSCs), known for their flexibility and efficiency in low light. To reduce this effect, manufacturers mostly wrap the cells with films, made of plastic, based on petroleum products, among others, polyethylene terephthalate. These plastics break down over time. In addition, they are difficult to recycle.

In their search for a bio-alternative, finnish researchers turned their attention to nanocellulose, a renewable material, derived from wood. It can be processed into thin, transparent films, that serve as an ideal base for cell, protection compounds solar panels from ultraviolet radiation.

Scientists painted these films with an extract from red onion peels. In this way, they managed to obtain a filter, that blocks 99.9% of ultraviolet radiation with a wavelength of up to 400 nm.

In solar cells, the key is to preserve visible and near-infrared light, as this is the part of the spectrum, used to generate electricity. A filter treated with an extract based on red onion peel, transmits more than 80% of light in the range of 650-1100 nm.

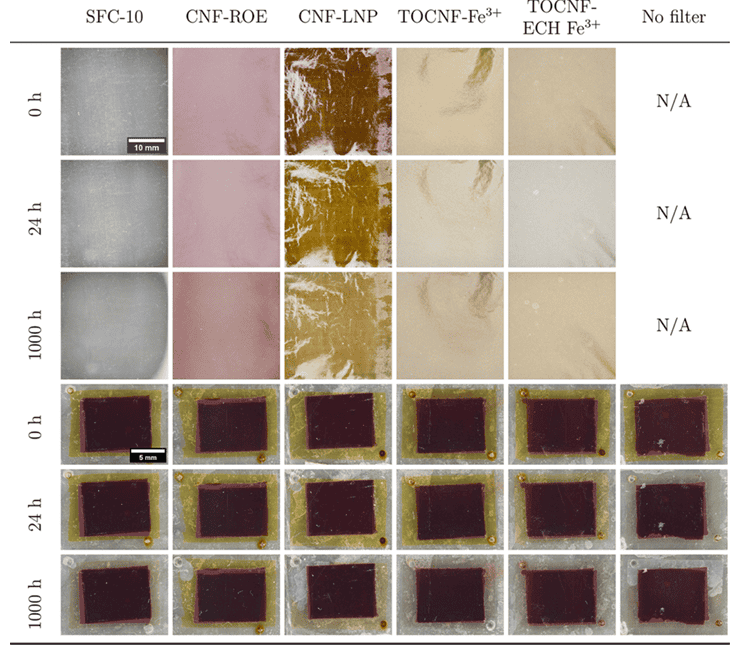

The researchers subjected the filters to rigorous tests. They kept them under artificial sunlight for 1 thousand hours. They attached the filters to DSSC and observed the degradation of the film and the solar cells, placed under it. Loss of color, in particular, yellowing or discoloration of the electrolyte, indicates the degradation of the basic chemical composition of the solar cell.

“The study emphasizes the importance of long-term testing of UV filters, as the UV protection and light transmission of other biofilters change significantly over time. For example, films, treated with iron ions, had good initial light transmission, which decreased over time”, — explains Rustem Nizamov.

The CNF-ROE film, which is a cellulose fiber with an extract of red onion peel, only slightly changed color and retained its yellow electrolyte tint, much better than any other filters. Predictive modeling based on previous degradation trends predicted, that CNF-ROE could extend the life of a solar cell to about 8,500 hours. At the same time, plastic-based filters ensure the operation of a solar cell for only 1.5 thousand hours.

The researchers also tested other types of biofilters. One of them contained iron ions, the second — lignin nanoparticles — a by-product of industrial paper production. Both filters showed promising results in the early stages of testing, but they degraded more rapidly under UV exposure. In particular, the films treated with iron (TOCNF-Fe³⁺), initially showed good UV protection, but later their transmittance and structural integrity decreased significantly.

At the same time, CNF-ROE biofilm has demonstrated a rare combination of durability, transparency, and stability. This is partly due to the pigment molecules anthocyanins, which give red onions their rich color and absorb ultraviolet light. In addition to this, the skin of red onions also contains flavonol glycosides and phenolic acids, which may contribute to additional stability.

Now, finnish scientists are planning to use biodegradable solar cells by combining them with remote sensors or wearable devices, especially if the recovery or further recycling of such devices is impractical. As solar panels become more widespread, the demand for environmentally friendly and durable materials will only grow. Currently most commercial solar modules still use plastic-based protective films.

Even the latest solar technologies, such as perovskite cells, remain extremely sensitive to UV radiation and are in dire need of more effective barriers. This is where a biodegradable material, that exceeds existing standards and is made from what, would otherwise be food waste, can make a quiet revolution.

The results are presented in the journal Applied Optical Materials

Source: ZMEScience

Spelling error report

The following text will be sent to our editors: