Japanese scientists from the The Center for Research on New Materials (RIKEN) was established a new type of plastic, is a recyclable material that dissolves in seawater, leaving no residue behind.

«We have created a new family of plastics that are strong, stable, recyclable, can fulfill many functions and, importantly, do not form microplastics. Children do not get to choose the planet they will live on. It’s our duty as scientists to provide them with the best possible environment», — said Takuzo Aida, a chemist at RIKEN.

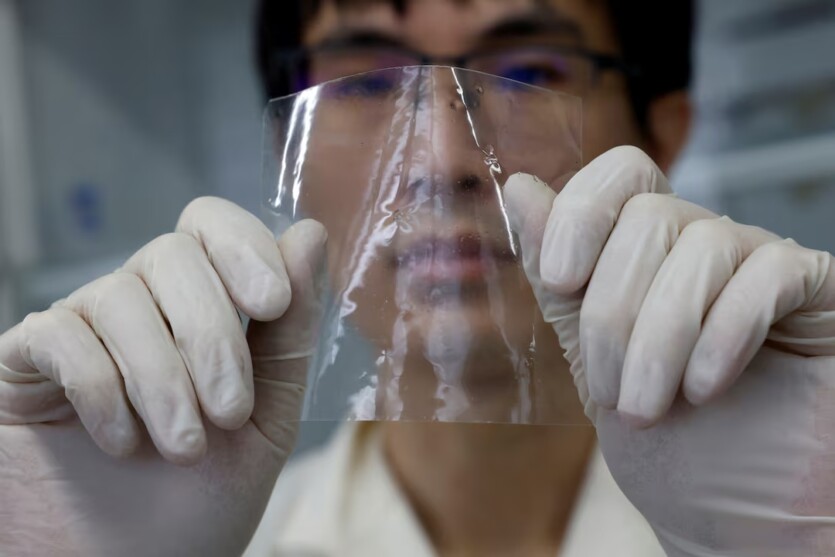

The plastic created by Japanese researchers is really strong and flexible, but it dissolves in salt water without a trace. It was made using ionic monomers. Its strength is ensured by salt bridges — electrostatic bonds that hold the material together. They break down when exposed to salt water, decomposing the plastic into harmless components.

A team of Japanese scientists led by Takuzo Aida was the first to describe the process of creating plastic from supramolecular assemblies. These materials are are created with the help of small reversible interactions.

«It was believed that the reversible nature of bonds in supramolecular plastics makes them weak and unstable. Our new materials are the exact opposite of», — explains Takuzo Aida.

The plastic, called alkyl SP2 has high strength, can be molded at temperatures above 120°C, and can be transformed into anything from hard shells to soft films. At the same time, unlike most biodegradable plastics, this material does not leave behind any microplastic particles. It can completely dissolve in seawater within 2-3 hours.

Although it takes longer, this plastic is also able to decompose in soil containing salt. In particular, a 5-cm piece takes about 200 hours to completely decompose in the soil. After decomposition, the components, including guanidinium ions and sodium hexametaphosphate, can be digested by natural soil bacteria into nutrients.

According to UN estimates, global plastic pollution could triple by 2040, increasing annual plastic waste emissions into the ocean by 23 to 37 million metric tons. Currently, successful recycling covers no more than 9% of all plastic waste.

Conventional plastics either hardly decompose or, when decomposed, form myroplastic particles that enter the body of animals and humans. Initially, Japanese researchers tried to solve the problem of plastic fragility. They made significant progress when they realized that removing excess salt would stabilize salt bridges, creating a strong and flexible film. Later, a repeated increase in salt content destroys this system and causes the plastic to decompose.

This one plastic does not emit carbon dioxide during decomposition, is non-toxic and does not catch fire. Once dissolved, more than 90% of its components can be recovered and reused, making it potentially recyclable and recyclable.

The researchers expect that the plastic they have created will be used primarily as a material for food packaging. Currently, the researchers are focused on finding the best coating options to extend the life of the plastic and make it possible to use it in 3D printing technologies, for more flexible packaging, and in medicine.

This material is literally alive — an alternative to plastic made from mushrooms

The results of the study are published in the journal Science

Source: ZMEScience

Spelling error report

The following text will be sent to our editors: